Expert Tips for Quality Control in Foundation Additions

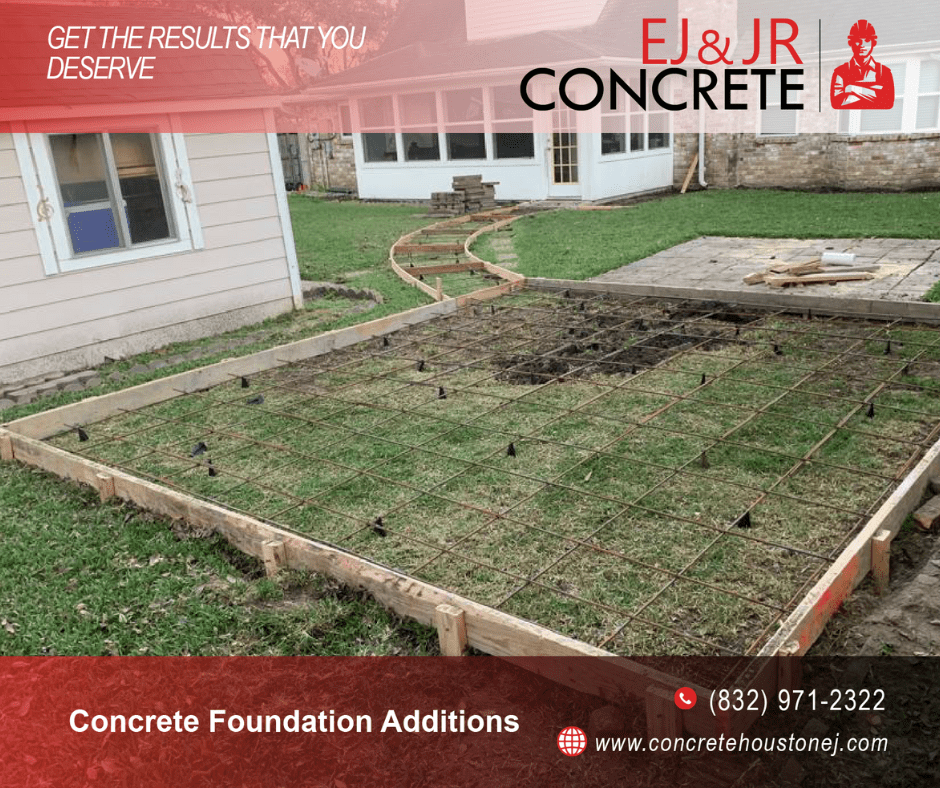

Concrete Foundation Additions in Houston

Introduction:

Adding a foundation to an existing structure is a complex process that requires careful planning, precision, and stringent quality control measures. Ensuring the foundation addition is of the highest quality is crucial for the stability and longevity of the entire building. In this article, we'll provide expert tips for maintaining quality control throughout the foundation addition process.

1. Initial Site Assessment

Before beginning any construction, a thorough site assessment is essential. This involves evaluating the soil conditions, checking for any underground utilities, and assessing the overall stability of the site. Proper site assessment helps in planning the foundation addition accurately and prevents future complications.

- Soil Testing: Conduct soil tests to determine its bearing capacity and suitability for the new foundation.

- Utility Checks: Locate and mark any underground utilities to avoid accidental damage during excavation.

- Site Clearance: Ensure the site is clear of debris and vegetation to provide a clean working area.

2. Detailed Planning and Design

Having a well-thought-out plan and design is crucial for the success of the foundation addition. This includes detailed drawings, specifications, and a clear timeline.

- Professional Design: Work with a structural engineer to create a detailed design that ensures the new foundation will integrate seamlessly with the existing structure.

- Specifications: Include precise specifications for materials, reinforcement, and construction techniques to be used.

- Timeline: Develop a realistic timeline that allows for each phase of the project to be completed without rushing, ensuring quality workmanship.

3. Selecting Quality Materials

The quality of materials used in the foundation addition plays a significant role in its durability and stability. Always choose high-quality materials that meet industry standards.

- Concrete Mix: Use a concrete mix that is appropriate for the load-bearing requirements and environmental conditions of the site.

- Reinforcement: Ensure the use of high-grade steel reinforcement bars that are free of rust and damage.

- Waterproofing: Apply waterproofing membranes or coatings to protect the foundation from moisture and water damage.

4. Skilled Workforce

The expertise of the workforce is a key factor in maintaining quality control. Hiring experienced and skilled professionals ensures that the foundation addition is constructed correctly.

- Training: Provide ongoing training to the workforce on the latest construction techniques and safety protocols.

- Supervision: Have a qualified supervisor on-site to oversee the construction process and address any issues promptly.

- Accountability: Foster a culture of accountability where each team member understands the importance of their role in maintaining quality.

5. Quality Control Inspections

Regular inspections are vital to ensure that each phase of the construction meets the required standards. Implement a robust quality control inspection process.

- Pre-Pour Inspections: Inspect formwork, reinforcement, and other preparations before pouring concrete to ensure everything is in place and meets specifications.

- Concrete Testing: Conduct slump tests and compressive strength tests on concrete samples to verify its quality.

- Post-Pour Inspections: After the concrete has cured, inspect for any defects, cracks, or issues that need addressing.

6. Documentation and Reporting

Maintaining detailed documentation and reporting throughout the project helps in tracking progress and ensuring accountability.

- Daily Reports: Keep daily logs of activities, inspections, and any issues encountered.

- Photographic Evidence: Take photographs at various stages of construction to provide visual records of the work done.

- Final Report: Compile a comprehensive final report documenting the entire process, including all quality control measures taken.

7. Post-Construction Maintenance

Once the foundation addition is complete, implementing a maintenance plan ensures its longevity and performance.

- Regular Inspections: Schedule periodic inspections to check for any signs of settling, cracks, or water damage.

- Maintenance Schedule: Develop a maintenance schedule that includes cleaning, waterproofing, and any necessary repairs.

Conclusion

Quality control in foundation additions is essential to ensure the safety, stability, and longevity of the entire structure. By following these expert tips, you can maintain high standards throughout the construction process and achieve a durable and reliable foundation addition. Investing in quality materials, skilled labor, and thorough inspections will pay off in the long run, providing peace of mind and structural integrity.

EJ & Jr Concrete is a family owned, all our work is guaranteed. No matter the size of your project, we are ready to do. Effective planning is crucial to the successful completion of any project. Before starting the project, our team of experts will first assess your goals. Then we provide you with an estimate and time-line for completion. From beginning to end you will be involved every step of the way call at +1 (832) 971-2322.

Call us at (832) 971-2322

11603 BLAIR MEADOW DR, STAFFORD, TX 77477 or mail us

Concrete Foundation Additions in Houston

Concrete Driveway in Houston, Concrete Patios in Houston, Concrete Sidewalk in Houston, Concrete Slab in Houston, Stamped Concrete Driveway in Houston, Stamped Concrete Patios in Houston, Stamped Concrete Sidewalk in Houston, Stamped Concrete Slab in Houston, Concrete Flatwork in Houston, Concrete Road Surface in Houston, Concrete Pool Deck in Houston, Concrete Garage in Houston, Concrete Interior Flooring in Houston, Concrete Foundation in Houston, Concrete Protection and Restoration in Houston, Stamped Concrete Flatwork in Houston, Stamped Concrete Road Surface in Houston, Stamped Concrete Pool Deck in Houston, Stamped Concrete Garage in Houston, Stamped Concrete Interior Flooring Stamped Concrete Foundation in Houston, Stamped Concrete Protection and Restoration in Houston, Stained Concrete Driveway in Houston, Stained Concrete Patios in Houston, Stained Concrete Sidewalk in Houston, Stained Concrete Slab in Houston, Stained Concrete Flatwork in Houston, Stained Concrete Road Surface in Houston, Stained Concrete Pool Deck in Houston, Stained Concrete Garage in Houston, Stained Concrete Interior Flooring in Houston, Stained Concrete Foundation in Houston, Stained Concrete Protection and Restoration in Houston, Epoxy Driveway in Houston, Epoxy Patios in Houston, in Houston, Epoxy Sidewalk Epoxy Slab in Houston, Epoxy Flatwork in Houston, Epoxy Road Surface in Houston, Epoxy Pool Deck in Houston, Epoxy Garage in Houston, Epoxy Interior Flooring in Houston, Epoxy Foundation in Houston, Epoxy Protection and Restoration in Houston.